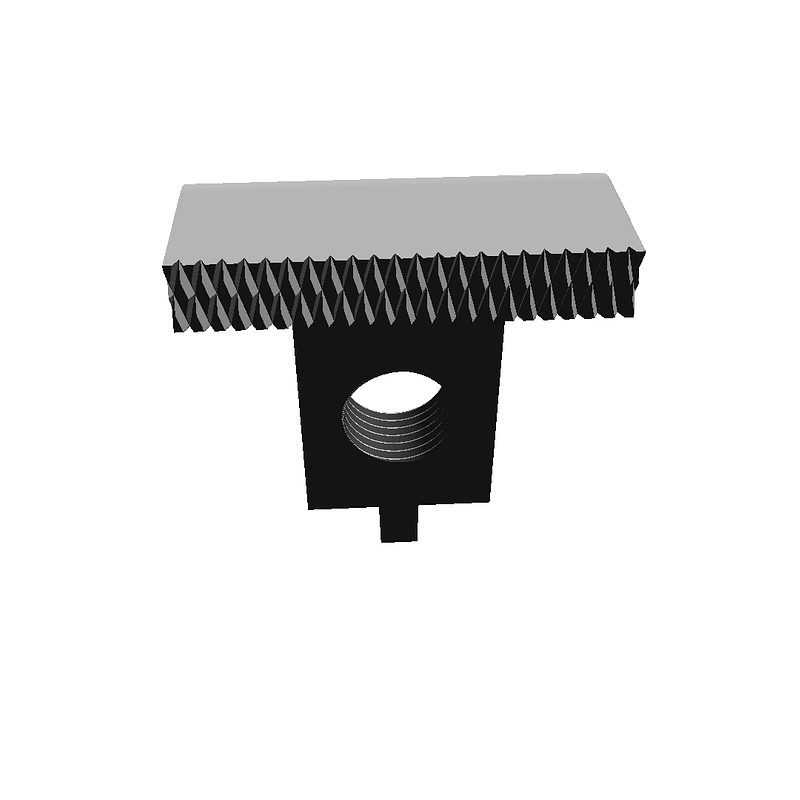

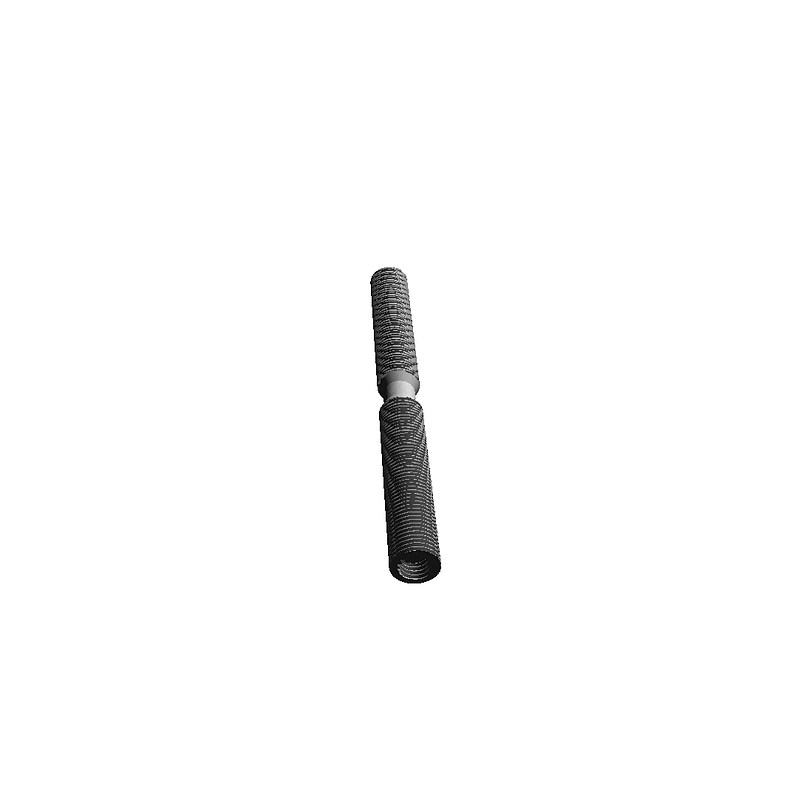

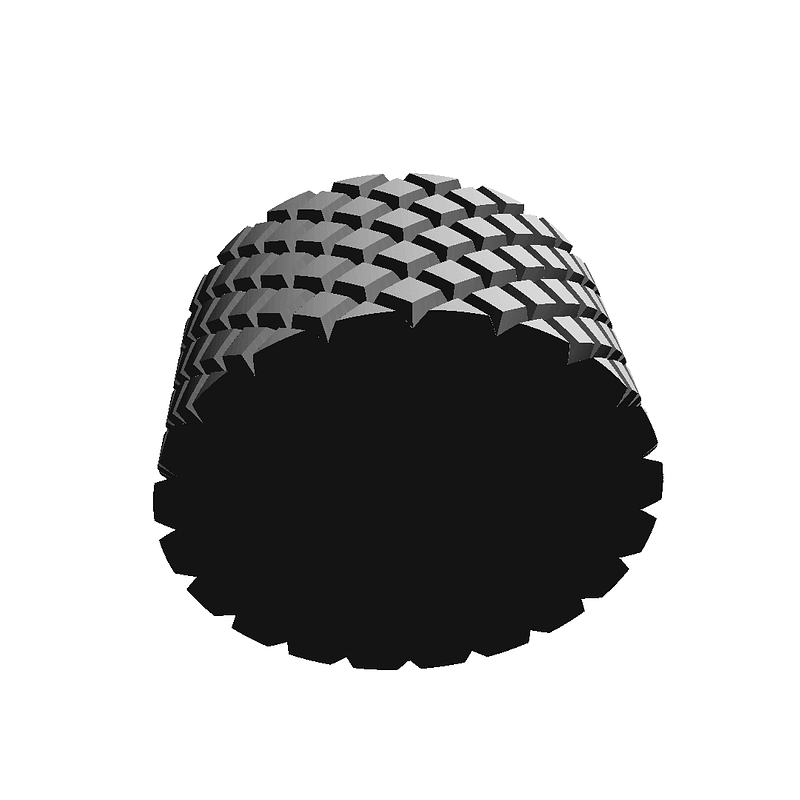

## Print Settings **Printer Brand:** Creality **Printer:** Ender 3 **Filament:** [RepRapper Red 3D Printer Filament PLA 1.75mm](https://amzn.to/2xHdjfO) ### In General This assembly is a very easy print except for the thread. Below I will go into detail into what is recommended to get the best results for each part, but this is a very easy print, and every printer should be able to do the whole thing in about 10 hours. This print doesn't require any supports or rafts, but the orientation and layer height is important, and other details are what I will discuss below. The times and material cost are also taking into considering printing that particular .stl alone, but you should be able to print the whole thing at one time.  The assembly should be a very straightforward print, no supports should be necessary, and you shouldn't need any rafts either. Since this is a functional part, the more infill, the better, 20% would probably be the minimum. I also do 5 layers for the top, bottom, and perimeters.   ### baseBottom.stl Build time: 1 hour 55 minutes Filament length: 11384.9 mm Plastic weight: 34.23 g (0.08 lb) Layer Height: .2 mm External Fill Pattern: I liked the look of concentric, but it shouldn't matter. Super easy print and could easily be printed at .3 mm if you wanted to. ### baseTop.stl Build time: 0 hours 19 minutes Filament length: 1151.6 mm Plastic weight: 3.46 g (0.01 lb) Layer Height: .2 mm External Fill Pattern: I liked the look of concentric, but it shouldn't matter. Infill: 30% Since this is the base of the model giving it more weight would be smart. Since this print has the tiny prongs anything higher than .2 mmm could make them super brittle. If you plan on gluing the model together, then this doesn't matter. ### xxxClamp.stl (Printing Together) Build time: 2 hours 17 minutes Filament length: 7945.1 mm Plastic weight: 23.89 g (0.05 lb) Layer Height: .15 mm Since these have threads, I would print them at a small layer height, but since this thread is so large in diameter, you should be able to get away with a bigger build height. ### thread.stl Build time: 6 hours 32 minutes Filament length: 5549.3 mm Plastic weight: 16.68 g (0.04 lb) raft: Your call Layer Height: .1 mm External Fill Pattern: Concentric Infill: 30% + The lower the layer height, the better the thread will turn out. The Ender 3 printed correctly at .1 mm even using a cheap filament. Do keep in mind that this only has about 150 mm^2 of area touching the build platform and if you have a printer where the build platform moves for the x-axis or y-axis 10 hours of moving back and forth can quickly knock it loose. So, if you have issues with prints adhering I would use a raft, and to be safe maybe even print the thread separate from the rest of the assembly. ### threadTwoEndCapDifficultPrint.stl Build time: 6 hours 32 minutes Filament length: 5510.6 mm Plastic weight: 16.57 g (0.04 lb) Raft: Yes Layer Height: .1 External Fill Pattern: Concentric Infill: 30% + The name makes it pretty clear that this is a problematic print for most prints, you have a long print with a meager 82mm^2 surface area touching the build platform. ### threadEnd.stl Build time: 0 hours 39 minutes Filament length: 939.3 mm Plastic weight: 2.82 g (0.01 lb) Layer Height: .1 mm External Fill Pattern: Concentric Super simple and quick print. I used a lower layer height since it makes the knurling look better, but since this thread isn't meant to attach more than once, the quality doesn't matter much. ### Entire Assembly at Once, Single Setting Build time: 9 hours 53 minutes Filament length: 27399.0 mm Plastic weight: 82.38 g (0.18 lb) Layer Height: .15 External Fill Pattern: Concentric Infill: 30% These are the settings to use for printing the entire assembly in under 10 hours. If you have issues with layer adhesion, I would print the thread.stl separate since it can be quite hard to print.

Loading...