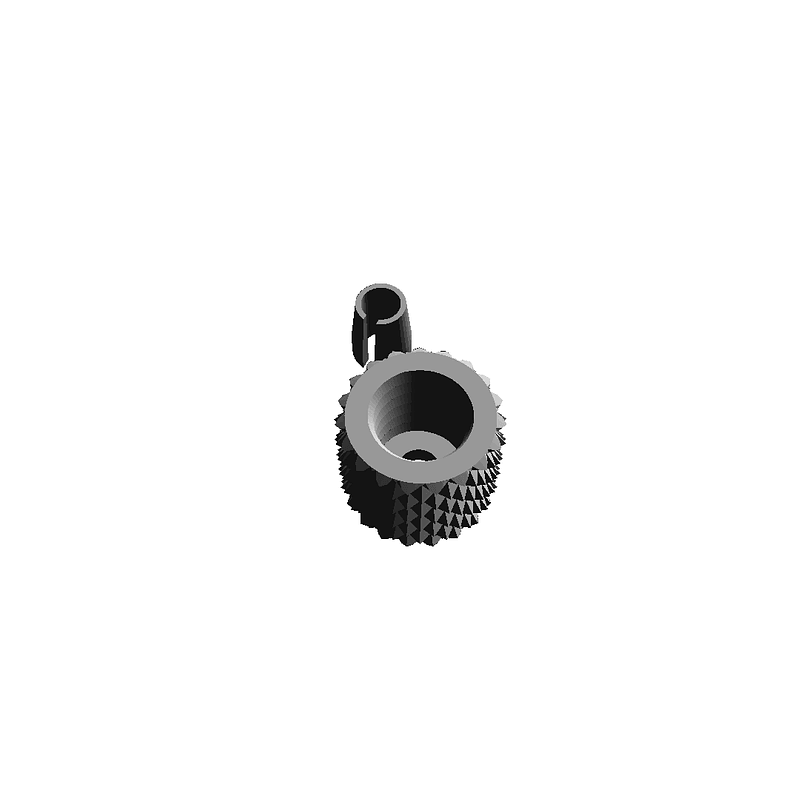

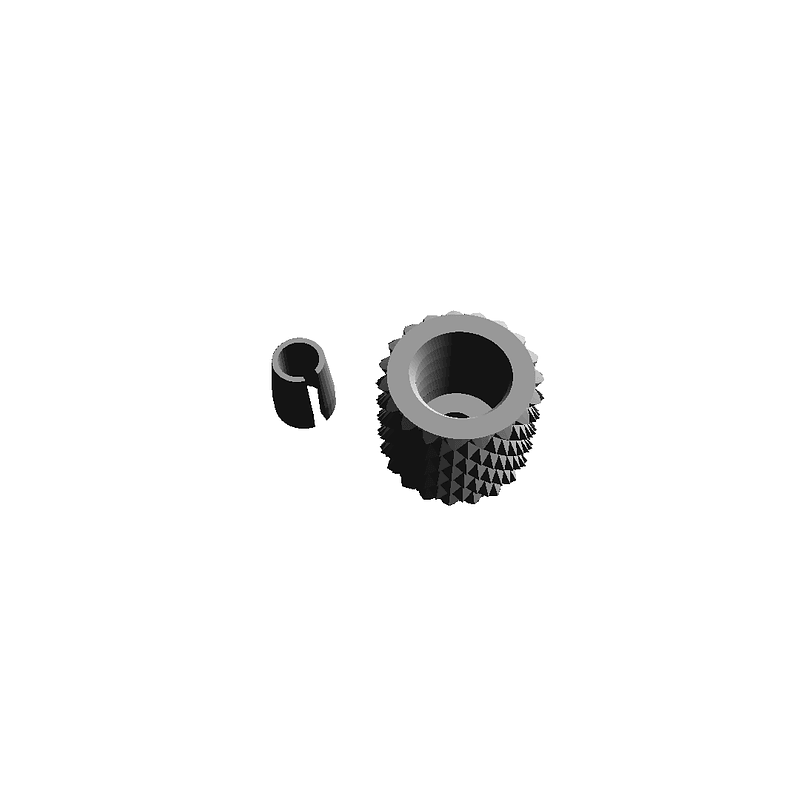

If you have a screw top HotEnd then; 1) Print the cap. 2) Put the bowden tube through the cap top. 3) wrap some ptfe tape (teflon) or other tape around the bowden tube near the end for a compression fit when the cap is installed. Remember to have the cap on first - Duh. Or you won't be able to put it on after you wrap tape on the tubing. In wrapping the tape I just wrapped the tape about 2-3 mm from the bowden tube end. I think I did 5 or 6 wraps. It needs to not slip through the cap top hole nor be too thick that you can't screw the cap on the hotend. I then cut the tape in half around the tube. This is because it was too wide and too much material to fit under the cap. I then removed half of the tape. Next, position the tube and put the cap down and screw on as straight as you can. You may hear some plastic fibers/threads cracking. That is OK. Check that the tube is secure by giving it a couple of tugs and print. Caution: I just built this and am not near having the printer work yet - So - your milage may vary. And the added compression collet is from jamesarm97. I'm not sure who may use this on this Hot End. It does not directly fit. Or if they will possibly drill out the cap or the Hot End screw top to accomodate this compression method over wrapping tape.

Loading...