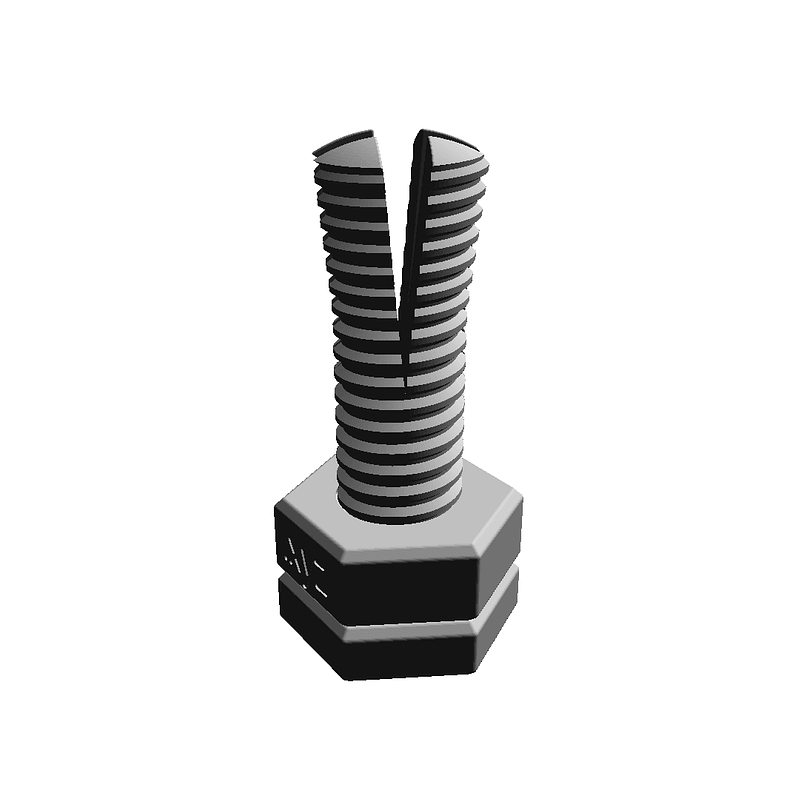

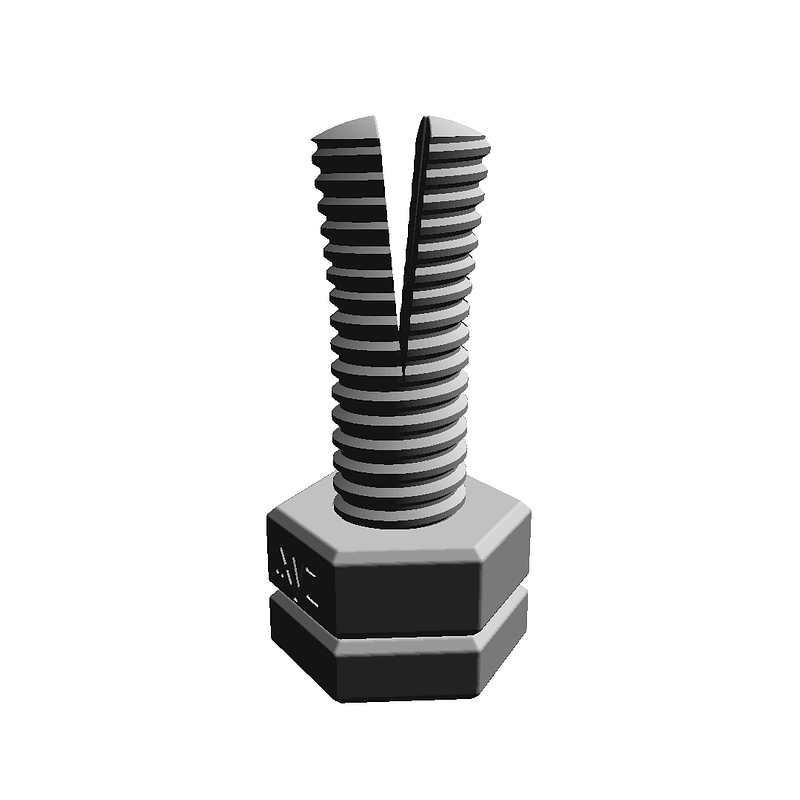

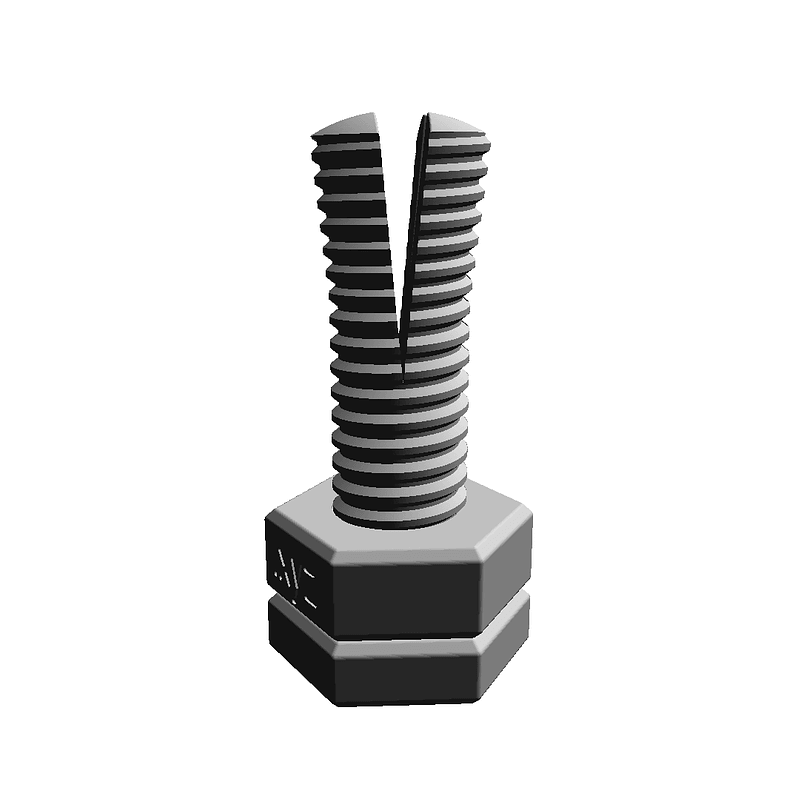

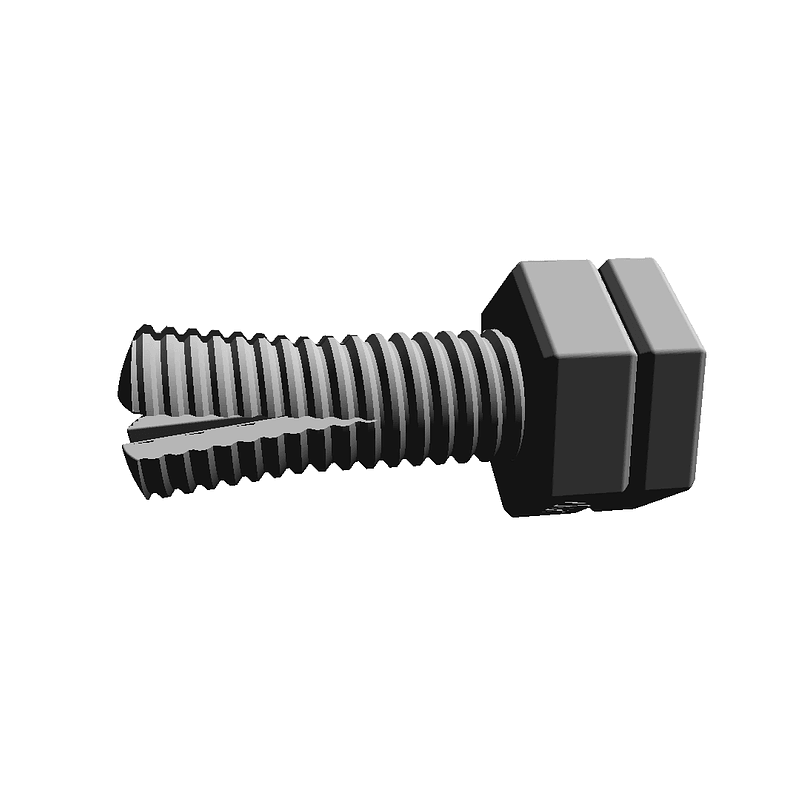

The gap There is a gap between the nut and the bolt's head. The size is adjusted so that the slicing software will "skip" a layer. This air gap should be small enough for the nut's first layer to adhere to the bolt's head, but still large enough for them to separate easily. We adjusted this gap so that it fits 3D-prints of PLA and ABS. Removing the nut from the bolt Make sure you don't cut yourself! Use a thin knife blad and insert it between the bolt's head and the nut. Wiggle it and move it around the bolt until you can feel than the majority of the gap is broken free. Remove the knife and carefully unscrew the nut. Choose the correct STL We provided several STL files in this thing to fit different 3D printer Z-heights. Choose the STL which fits your 3D printer and scale it slightly if needed. The important thing is not to affect the gap too much when scaling the bolt.

Loading...